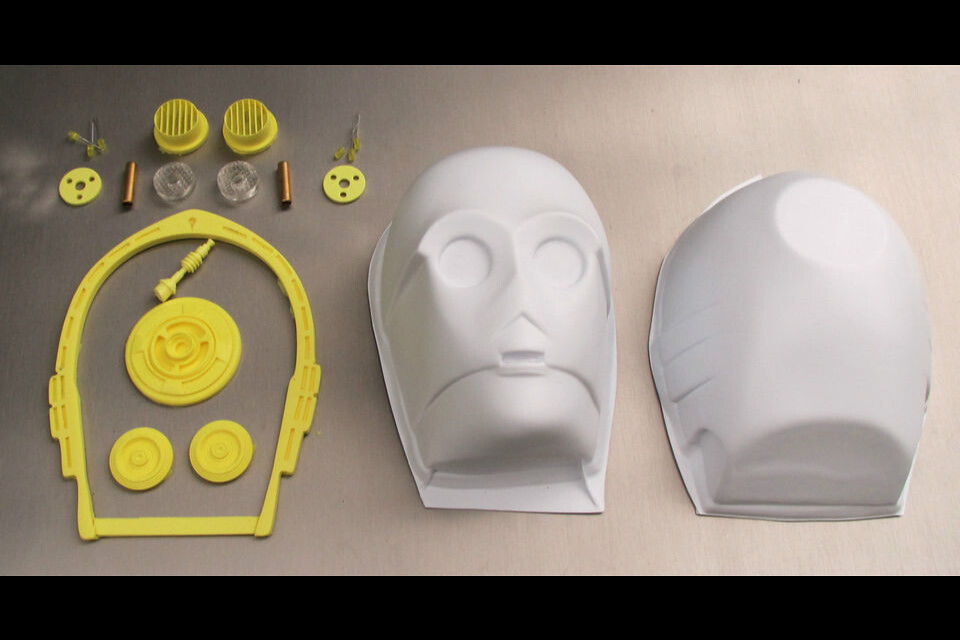

A while back i got hold of a nice little C3PO helmet kit, its not perfect but its still pretty damn good, and i love it.

The kit came with all the parts you need to make the head of your very own protocol droid.

You get the front and back shells of the head (vac formed)

Resin neck bolts.

Resin halo, to go inside the rear shell of the head.

Resin rear detail for the back of the head.

Resin antenna

multiple parts for the eyes.

It even came with some nice colour accurate LED's for the eyes.

The first step i took was to cut the flat section out of the rear shell to the same size as the raised detail section of the rear 'plug' i then glued the detailed plug in to the hole and made sure it was the correct rotation.

I then glued the halo into the rear shell at the right depth, there was some extra plastic around the halo as the vac form was pulled with extra which was perfect to get it in the right place and flush against the halo.

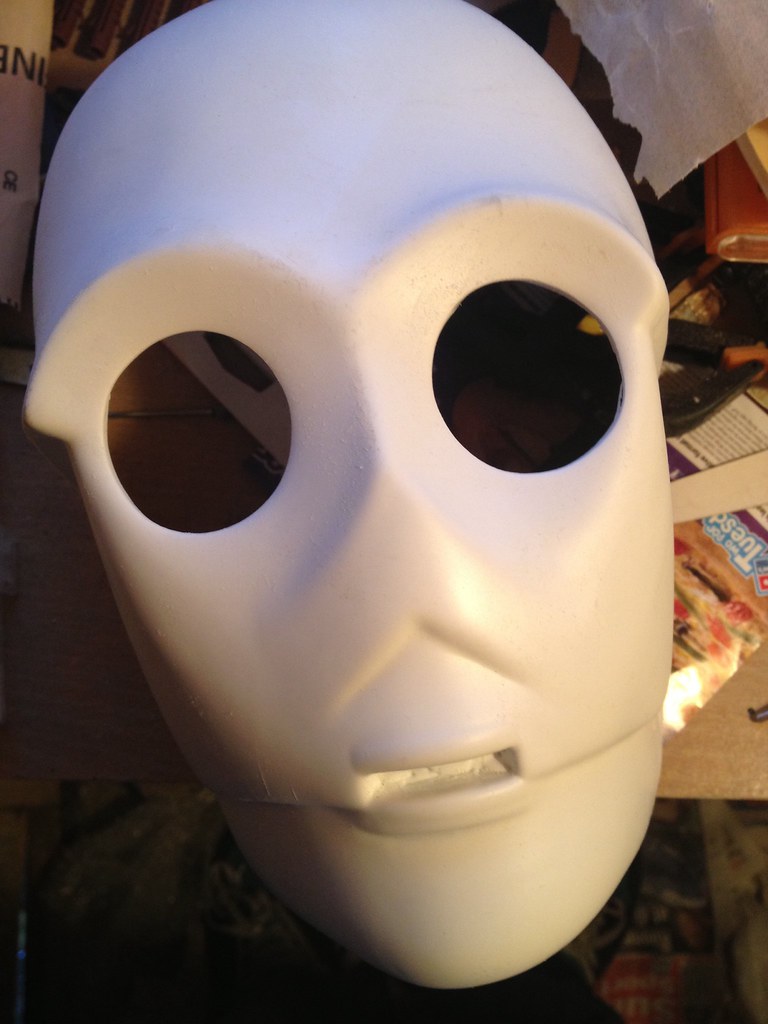

The eye holes were the next thing to be cut out.

I started by trimming them out to the line in the shell and test fitting the eyes the holes were slightly too small so i then began slowly sanding the edge of the hole until the eyes fit inside the shell.

I didn't glue them in place as this was just a test fit.

The front plastic shell has to fit inside the halo so the halo will have to be sanded and shaped to fit the shape of the front of the head.

This process is a slow one as i needed to do it bit by bit to make it flush.

In one place i went to far so i had to fill it and re-shape and get it to fit.

I did a little test of fitting all the parts together and i put a torch inside just for fun to see how his eyes might look lit up.

On the rear detailed section i filled the gap between the resin plug and the plastic shell and sanded it flush and gave it a coat of primer and then filled any gaps i missed the first time round.

I did the same for the gaps around the halo and the rear shell.

Test fit of the face after priming and sanding.

At this point i made the dent on his forehead. i did this by heating a small section of the front shell with a heat gun and then i pressed it in when it was pliable.

(i forgot to take a photo but you will see the result lower down.)

I painted the whole lot (everything that's going to be gold) with a base coat of black and then a layer of chrome silver from plasticoat. i sprayed the sliver on top of the black in phases i did a light coat of silver when the black was still wet, then once all that had dried i gave it a full coat of silver.

I let the all the paint dry full for a good few hours. (the chrome paint takes a long time to dry and it may feel/look dry but if you hold it for to long you will leave fingerprints in it.)

Using silicone i then dabbed it on places that i thought would be where the gold paint would have flaked off, high places, parts of him that would have been hit or scratched.

Then i gave everything a coat of gold plasicoat chromed gold. (which is a lot higher gloss than i thought. much much better. )

The bumpy sections on the eye brows and nose etc. are the sections that have the silicone under the gold. The silicone will be rubbed off when dry and reveal the silver underneath.

Here's what the paint looks like when the silicone is removed

Test fit, the silicone has not been removed from the front face yet.

The silicone on the front shell has been removed (first pic) eyes glued into place.(second pic)

Test video of the sound chip with all the sounds.

I got a sound chip from ebay. Its designed to be used in a greetings card or something like that.

you can connect it to your computer to load up what ever sound you want.

The version i have has five buttons so you can upload five different sounds.

This video was filmed before i did the final weathering of the head.

I weathered the whole head, the idea was the make it look like he has been through the wars, scarred up and like hes been blasted in the desert

i did the weathering with different techniques, i started with a very fine sand paper to dull down sections of the gold, mainly round the silver flaked sections and high points.

I also used plain printer paper to rub down sections as this dulls the paint down with out scratching or removing the paint like the sand paper does.

once i was happy with the paint dulling i started with colour washes, doing lots of light dry-brushes of different coloured yellows light browns and dark browns for dust rust and dirt.

once i dry-brushed and wiped off the excess paint over and over to build up loads of layers i did some a bit of black wash, i blacked the joins between the two halves and around the eyes and mouth and in the recesses in the halo to give it some depth and dimension.

I decided to give C3PO a little bit of oil mess on the rear plug on the back of his head.

All the cables coming out the back of the neck hole of C3PO are the buttons and switches for the lights and sounds.

I am going to leave them hanging out the neck as this is a decapitated C3PO so he would have cables and wires out of his neck.

I am planning on capping the neck and making a neck joint where all the wires will come out and then it will sit on a stand so you can access the buttons etc.

I hope you enjoyed my write up, or learned something.

If you have any questions or comments please feel free to leave a comment below.

Thanks.